| |

| |

| Names | |

|---|---|

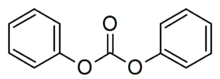

| Preferred IUPAC name

Diphenyl carbonate | |

| Other names

Phenyl carbonate, di- | |

| Identifiers | |

| |

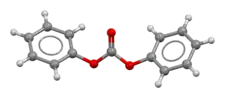

3D model (JSmol) |

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.002.733 |

| KEGG | |

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C13H10O3 | |

| Molar mass | 214.216 g/mol |

| Density | 1.1215 g/cm3 at 87 °C |

| Melting point | 83 °C (181 °F; 356 K) |

| Boiling point | 306 °C (583 °F; 579 K) |

| insoluble | |

| Solubility | soluble in ethanol, diethyl ether, carbon tetrachloride, acetic acid[1] |

| Hazards | |

| GHS labelling: | |

| |

| Warning | |

| H302, H410, H411 | |

| P264, P270, P273, P301+P312, P330, P391, P501 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

Diphenyl carbonate is the organic compound with the formula (C6H5O)2CO. It is classified as an acyclic carbonate ester. It is a colorless solid. It is both a monomer in combination with bisphenol A in the production of polycarbonate polymers[2][3] and a product of the decomposition of polycarbonates.[4]

Production

World production capacity of diphenyl carbonate was 254,000 tonnes in 2002, and phosgenation of phenol is the most significant route.[5] Phosgenation of phenol can proceed under various conditions. The net reaction is as follows:

- 2 PhOH + COCl2 → PhOCO2Ph + 2 HCl

The use of phosgene can be avoided by the oxidative carbonylation of phenol with carbon monoxide:[2]

- 2 PhOH + CO + [O] → PhOCO2Ph + H2O

Dimethyl carbonate can also be transesterified with phenol:

- CH3OCO2CH3 + 2 PhOH → PhOCO2Ph + 2 MeOH

The kinetics and thermodynamics of this reaction are not favorable. For example, at higher temperatures, dimethyl carbonate undesirably methylates phenol to give anisole.[2] Despite this, diphenyl carbonate made from non-phosgene sources has become a widely used raw material for the synthesis of bisphenol-A-polycarbonate in a melt polycondensation process.[6]

Applications

Polycarbonates can be prepared by transesterifying diphenyl carbonate with bisphenol A. Phenol is a co-product. These polycarbonates may be recycled by reversing the process: transesterifying the polycarbonate with phenol to yield diphenyl carbonate and bisphenol A.[2]

References

- ↑ Lide, David R. (1998), Handbook of Chemistry and Physics (87 ed.), Boca Raton, FL: CRC Press, pp. 3–238, ISBN 0-8493-0594-2

- 1 2 3 4 Hans-Josef Buysch (2000). "Carbonic Esters". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a05_197. ISBN 978-3527306732.

- ↑ Wittcoff, Harold; Reuben, B. G.; Plotkin, Jeffrey S. (2004), Industrial Organic Chemicals, Wiley-IEEE, p. 278, ISBN 978-0-471-44385-8, retrieved 2009-07-20

- ↑ ASM International (2003), Characterization and Failure Analysis of Plastics, ASM International, p. 369, ISBN 978-0-87170-789-5, retrieved 2009-07-20

- ↑ "Diphenyl Carbonate" (PDF). IPSC Inchem. Retrieved 2012-08-01.

- ↑ Fukuoka, Shinsuke (2012). Non-Phosgene Polycarbonate from CO2 - Industrialization of Green Chemical Process. Nova Science Publishers. ISBN 9781614708773.