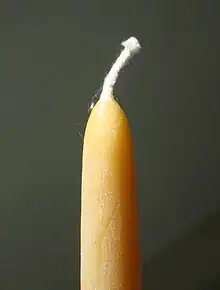

A candle wick or lamp wick is usually made of braided cotton that holds the flame of a candle or oil lamp. A candle wick works by capillary action, conveying ("wicking") the fuel to the flame. When the liquid fuel, typically melted candle wax, reaches the flame it then vaporizes and combusts. In other words, the wick brings the liquified wax up into the flame to burn.[1] The candle wick influences how the candle burns. Important characteristics of the wick include diameter, stiffness, fire-resistance, and tethering.

Wick types

Wicks are sometimes braided flat, so that as they burn they also curl back into the flame, thus making them self-consuming. The wick sizes determine the amount fuel brought into the flame. [1]Prior to the introduction of these wicks specialty scissors were used to trim the excess wick without extinguishing the flame.[2]

Large diameter wicks typically result in a larger flame, a larger pool of melted wax, and the candle burning faster.

In tealights, the wick is tethered to a piece of metal to stop it from floating to the top of the molten wax and burning before the wax does. Candles designed to float in water require not only a tether for the wick, but also a seal on the bottom of the candle to prevent the wick from wicking water and extinguishing the flame.

Wicks can be made of material other than string or cord, such as wood and (historically) even asbestos, although they are rare. The 17th century rushlight and rushcandles also uses rush-pith. The cotton of tampons can be used as wicks for oil lamps in wilderness survival situations.[3]

Specific wick types

Zinc core wicks- most popular and the core allows the wick to stand up straight

CD series wicks- flat braided with paper woven in it and promotes maximum and consistent burn

ECO series wicks- made for natural waxes and has controlled curling of the wick which allows self-trimming

HTP series wicks- core-less braided wicks and curling of top of wick which allows complete combustion

LX series wicks- flat braided wicks that are chemically treated with a high melt point wax and reduces smoke and soot

Wooden wicks- relatively new to candle making and could be soft or hard wood

History of the candle wick

Wicked candles initially started to be used by ancient Egyptians in 3000 B.C. Wicked candles were assumed to be made by waxes from available plants and animals in this time period. [5]

During this time, the Chinese were using rice paper to create wicks and made wax out of insects and seeds. [6]

Stiffeners

Stiffeners are used to direct the wick to remaining upright so that fuel can get to the flame. [7] This provides two advantages: it makes the wick more rigid, letting it stand further out of the liquid wax, and it conducts heat downward, melting the wax more readily. The latter is particularly important in candles made of harder wax.

Stiffeners were once made of lead, but these have been banned in the US for several years by the Consumer Product Safety Commission, due to the concerns about lead poisoning. Fine wire (such as copper) can be included in the wick. Other core stiffeners, such as paper and synthetic fibers, may also be used. The CPSC was petitioned to ban candle wicks containing lead cores and candles with such wicks by Public Citizen, the National Apartment Association, and National Multi Housing Council on February 20, 2001. The ban against manufacturing, importing, or selling candles in the US with lead wicks became effective in October 2003.[8]

Pretreatments of wicks

Virtually all wicks are treated with various flame-resistant solutions in a process known as mordanting. Without mordanting the wick would be destroyed by the flames and the flow of melted wax to the flame would cease. Beyond that, wicks can be treated with substances to improve the color and brightness of the flame, provide better rigidity to keep the wick out of the melted wax, and improve the flow of that wax up the wick. Common treatments are borax and salt which are dissolved in water in which the wicks are soaked. Wicks can also be pretreated with paraffin wax. [9]

See also

References

- 1 2 "Elements of a Candle: Wicks". National Candle Association. Retrieved 2023-12-05.

- ↑ Michelle J. Ferry (18 October 2017). "How To Trim a Candle Wick & Why You Should Do It". graciemoonscents.com. Archived from the original on 2 December 2021. Retrieved 22 July 2019.

- ↑ Creek Stewart (27 March 2012). "Yes, that's a Tampon in my mouth : The Swiss Army Survival Tampon : 7 Survival Uses". WillowHavenOutdoor.com. Archived from the original on 2014-01-15. Retrieved 5 January 2014.

- ↑ "Guide to Candle Wicks | How to Decide Which Wick To Use". lonestarcandlesupply.com. Retrieved 2023-12-05.

- ↑ "History". National Candle Association. Retrieved 2023-12-05.

- ↑ York, LAFCO New (2023-01-30). "The History of Candle Making: From Ancient Civilizations to Modern Day". LAFCO New York. Retrieved 2023-10-24.

- ↑ "Candle Wicks - A Detailed And Informative Guide Into All Things Wicks!". All Seasons Wax Company. 2018-07-26. Retrieved 2023-12-05.

- ↑ "CPSC Bans Candles with Lead-Cored Wicks". Archived from the original on March 6, 2012. Retrieved July 24, 2012.

- ↑ "Candle wicks - How to prime wicks and why? • HowtomakeCandles.info". www.howtomakecandles.info. Retrieved 2023-12-05.

External links

![]() Media related to Cotton wicks at Wikimedia Commons

Media related to Cotton wicks at Wikimedia Commons