A closure is a device used to close or seal a container such as a bottle, jug, jar, tube, or can. A closure may be a cap, cover, lid, plug, liner, or the like. The part of the container to which the closure is applied is called the finish.[1]

Other types of containers such as boxes and drums may also have closures but are not discussed in this article. Many containers and packages require a means of closing, which can be a separate device or seal or sometimes an integral latch or lock.

Purpose of closures

The closure is often the most critical part of a package, and must fulfill all of the basic functions of packaging in addition to being easy to open and (if applicable) reclose.[2]

Depending on the contents and container, closures have several functions:

- Keep the container closed and the contents contained for the specified shelf life until time of opening

- Provide a barrier to dirt, oxygen, moisture, etc. Control of permeation is critical to many types of products: foods, chemicals, etc.

- Keep the product secure from undesired premature opening

- Provide a means of reclosing or reusing the container

- Assist in dispensing and use of product

- Allow reasonable ease to open the container by the intended user. Difficult to open containers may cause wrap rage. The force or torque required to open a closure is an important consideration for packaging engineers.[3][4]

Many types of packaging with their closures are regulated for strength, safety, security, communication, recycling, and environmental requirements plus many others.

Types of closures

Closures need a means of attaching to the container with sufficient security. Threads, lugs, hinges, locks, adhesives, etc. are used. Many plastic closures are made by injection molding.[5]

Many closures need to have the ability to adjust to slight manufacturing variation in the container and the closure structure. Some closures are made of flexible material such as cork, rubber, or plastic foam. Often an o-ring or a closure liner (gasket made of pulp or foam cap liner) is used. Linerless closures often use a deformable plastic rim or structure to maintain the seal.

Secondary seals are common with sensitive products that may deteriorate or where extra security is needed. Foil or plastic inner seals are used on some bottles, Heat sealed lidding films are used on some tubs. External shrink bands, labels, and tapes are sometimes used outside the primary closure structure. Additionally, many closures feature ventilation to prevent bloating, collapse or explosion due to unequalized pressure during processing or storage. Venting technologies utilize common materials such as PTFE, PP, etc. These elements are preferred due to their ability to withstand temperatures of 260 °C and water intrusion pressure levels of 770 mbar.[6]

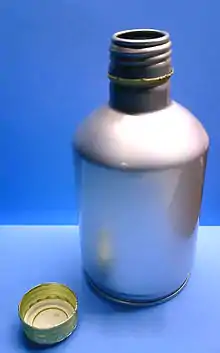

Screw top

A screw closure is a mechanical device which is screwed on and off of a threaded "finish" on a container. Either continuous threads (C-T) or lugs are used. Metal caps can be either preformed or in some instances, rolled on after application. Plastic caps may use several types of molded polymer.

Some screw tops have multiple pieces. For example, a mason jar often has a lid with a built in rubbery seal and a separate threaded ring or band.

Crown cap

Beverage bottles are frequently closed with crown beverage caps. These are shallow metal caps that are crimped into locking position around the head of the bottle.

Snap on

Some closures snap on. For opening, the top is designed to pry off or, break off, or have a built in dispenser.

Friction fit

Some containers have a loose lid for a closure. Laboratory glassware often has ground glass joints that allow the pieces to be fitted together easily.

An Interference fit or friction fit requires some force to close and open, providing additional security. Paint cans often have a friction fit plug.

Tamper-evident

Resistance to tampering is required for some types of products. Container closures can be one of several layers of packaging to deter tampering and to provide evidence of attempts at tampering. *Sometimes tamper resistance is obtained by a tamper-evident band; separate or integral with the closure.[7][8] [9]

Dispensing

A wide variety of convenience dispensing features can be built into closures. Spray bottles and cans with aerosol spray (valves, actuator) have special closure requirements. Pour spouts, triggers, sprayer cap, measuring attachments, sifting devices, etc. are common caps.

Spray bottle

A spray bottle is a bottle that can dispense, squirt, spray or mist fluids. A common use for spray bottles is dispensing cool cleaners, cosmetics, and chemical specialties.

Child-resistant

Child-resistant packaging or C-R packaging has special closures designed to reduce the risk of children ingesting dangerous items. This is often accomplished by the use of a special safety cap. It is required by regulation for prescription drugs, over-the-counter medications, pesticides, and household chemicals.

Examples

Spray bottle cap

Spray bottle cap rubber stoppers on flasks

rubber stoppers on flasks spray duster with long tube for dispensing

spray duster with long tube for dispensing Closure and roll-on device for deodorant

Closure and roll-on device for deodorant Inverted ketchup bottle with innerseal and dispensing closure

Inverted ketchup bottle with innerseal and dispensing closure Bottle of Geritol with a child-resistant cap

Bottle of Geritol with a child-resistant cap An opened flip-top bottle closure

An opened flip-top bottle closure A screw cap capsule is fitted onto a wine bottle and heat shrunk tightly

A screw cap capsule is fitted onto a wine bottle and heat shrunk tightly Recycled bottle stoppers as art in Vienna

Recycled bottle stoppers as art in Vienna A living hinge on the lid of a Tic Tac box

A living hinge on the lid of a Tic Tac box

History

Early pottery and ceramic containers often had lids that fit reasonably snug onto the body of the container. The narrow necks of ancient amphora were closed with a plug of cork, wood, or ceramic and sealed with mortar.[10] Wooden Barrels often had bungholes closed by cork or wood bungs.

Some early tinplate cans were made with threaded necks for screw top closures.

Beverage bottles started using the Hutter Stopper in 1893. This involved a porcelain plug fitted with a rubber washer, which was then forced down into the lip of the bottle. This technique only works with carbonated beverages. The Hutter Stopper became standard in beer bottling in the late 1890s / early 1900s. Bail closures on bottles were invented by Henry William Putnam in 1859. These involved heavy wire bail attached to a bottle's neck that swung over the cork to hold it in.

The world's first modern bottle cap, the crown cork, was invented by William Painter in 1890 in Baltimore. The screw cap using rust resistant aluminum was first used in prescription drug bottling in the 1920s. Molded urea based bottle caps were first introduced in the early 1900s.

A history of accidents involving children opening household packaging and ingesting the contents led the US Congress to pass the Poison Prevention Packaging Act of 1970.

Greek pottery with lid, 5th century

Greek pottery with lid, 5th century An assortment of wine corks

An assortment of wine corks bail closure on jam jar

bail closure on jam jar

The manufacture of closures

The International Society of Beverage Technologists (ISBT) is the main trade association for closure manufacturers. It develops voluntary industry standards for its members to use in the manufacture of closures.

See also

- Bottle cap

- Crown cork

- GPI container finish standards which includes closures for glass containers

- Hutchinson Patent Stopper

- Lid (container)

- Screw cap

- Stopper (plug)

- Tab (beverage can)

- Tamper resistant

- Tamper-evident

References

- ↑ Smith, J. Scott; Hui, Y. H. (2008). Food Processing: Principles and Applications. John Wiley & Sons. p. 129. ISBN 9780470289976.

- ↑ Smith & Hui 2008, p. 123.

- ↑ Yoxall, A; J. Langley; R. Janson; J. Wearn; G. Manson (2006). "The Use of Uncertainty Analysis for Design of Container Closures". Packaging Technology and Science. Wiley. 19 (3): 139–147. doi:10.1002/pts.716. S2CID 109492532.

- ↑ Carus, D. A.; C. Grant; R. Wattie; M. S. Pridham (2006). "Development and Validation of a Technique to Measure and Compare the Opening Characteristics of Tamper-evident Bottle Closures". Packaging Technology and Science. Wiley. 19 (2): 105–118. doi:10.1002/pts.721. S2CID 110675079.

- ↑ Sievers, R M (2005), SIMULATING THE POLYPROPYLENE FILLING OF A DISPENSING CLOSURE MOLD WITH INJECTION MOLDING SOFTWARE (PDF), 2005 IL/IN Sectional Conference: American Society for Engineering Education, retrieved 18 May 2021

{{citation}}: CS1 maint: location (link) - ↑ "Venting Filters: Porous Venting Material & Technology by Porex". www.porex.com. Retrieved 2017-04-11.

- ↑ US 6550626 B1, Randall, "Closure lid and resealable closure system with tamper-evident features", published 2003

- ↑ US 3904062 A, Grussen, "Tamper-proof and loss-proof screw-type bottle cap", published 1975

- ↑ US 5913437 A, Xiaoli Ma, "Tamper evident bottle cap", published 1999

- ↑ Tweede, D (June 2002), "Commercial Amphoras, the First Consumer Package" (PDF), Journal of Macromarketing, 22, 1: 185–198, archived from the original (PDF) on 2011-07-16, retrieved 2010-02-02