| |

| Names | |

|---|---|

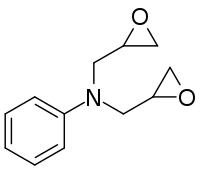

| IUPAC name

N,N-bis(oxiran-2-ylmethyl)aniline | |

| Other names

Diglycidylaniline; Bis(2,3-epoxypropyl)aniline; Bis(epoxypropyl)phenylamine; Diglycidyl aniline; N,N-Bis(2,3-epoxypropyl)aniline; N,N-Di(2,3-epoxypropyl)aniline; N,N-Diglycidylaniline; N-(Oxiranylmethyl)-N-phenyloxiranemethanamine; N-N-Diglycidylphenylamine; N-(2-oxiranylmethyl)-N-phenyl-2-oxiranemethanamine; N,N-bis(2,3-epoxypropyl)-aniline; N-(oxiranylmethyl)-N-phenyl-oxiranemethanamine | |

| Identifiers | |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.016.599 |

| EC Number |

|

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C12H15NO2 | |

| Molar mass | 205.255 g/mol |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

Diglycidyl aniline is an aromatic organic chemical in the glycidyl compound family.[1] It is used to reduce the viscosity of epoxy resin systems.[2] It has the empirical formula C12H15NO2 and the IUPAC name is N,N-bis(oxiran-2-ylmethyl)aniline. The CAS number is 2095-06-9.[3][4] It is REACH registered in Europe with the EC number 218-259-5.[5] A key use is in the viscosity reduction of epoxy resin systems functioning as a reactive diluent.[6][7]

Alternative names

Manufacture and synthesis

Many glycidyl ethers are manufactured by addition of epichlorohydrin to a species with the aid of a Lewis acid as catalyst to form a halohydrin. This process is followed by washing with sodium hydroxide in a dehydrochlorination reaction.[10] This diglycidyl compound being basic and nitrogen based, does not need this type of catalyst.[11][12] One of the quality control tests would involve measuring the Epoxy value by determination of the epoxy equivalent weight in addition to viscosity.

Uses

The use of the diluent in epoxy systems affects the mechanical properties and microstructure of epoxy resins.[13][14][15][16][17] The kinetics of cure of this Diglycidyl amine with epoxy resin networks have been studied.[18] It has also been used to synthesize other materials including ion-exchange resins.[19][20][21]

Toxicity

The toxicity profile has been studied and published.[22]

References

- ↑ "diglycidylaniline - MeSH - NCBI". www.ncbi.nlm.nih.gov. Retrieved 2022-08-04.

- ↑ Dušek, Karel (1989), Lemstra, P. J.; Kleintjens, L. A. (eds.), "Curing of Epoxy Matrices", Integration of Fundamental Polymer Science and Technology—3, Dordrecht: Springer Netherlands, pp. 265–273, doi:10.1007/978-94-009-1115-4_30, ISBN 978-94-009-1115-4, retrieved 2022-08-04

- ↑ PubChem. "Diglycidylaniline". pubchem.ncbi.nlm.nih.gov. Retrieved 2022-08-04.

- ↑ PubChem. "2095-06-9". pubchem.ncbi.nlm.nih.gov. Retrieved 2022-08-04.

- ↑ "Substance Information - ECHA". echa.europa.eu. Archived from the original on 2022-04-11. Retrieved 2022-04-11.

- ↑ EP 2621994, Hefner, Robert E., "Epoxy resin compositions", published 2013-08-07, assigned to Dow Global Technologies LLC

- ↑ Jagtap, Ameya Rajendra; More, Aarti (2022-08-01). "Developments in reactive diluents: a review". Polymer Bulletin. 79 (8): 5667–5708. doi:10.1007/s00289-021-03808-5. ISSN 1436-2449. S2CID 235678040.

- ↑ PubChem. "N,N-bis(oxiran-2-ylmethyl)aniline". pubchem.ncbi.nlm.nih.gov. Retrieved 2022-08-04.

- ↑ PubChem. "2095-06-9". pubchem.ncbi.nlm.nih.gov. Retrieved 2022-08-04.

- ↑ Crivello, James V. (2006). "Design and synthesis of multifunctional glycidyl ethers that undergo frontal polymerization". Journal of Polymer Science Part A: Polymer Chemistry. 44 (21): 6435–6448. Bibcode:2006JPoSA..44.6435C. doi:10.1002/pola.21761. ISSN 0887-624X.

- ↑ Panda, Dr H (2019). Epoxy Resins Technology Handbook (Manufacturing Process, Synthesis, Epoxy Resin Adhesives and Epoxy Coatings (2nd ed.). Asia Pacific Business Press Inc. p. 38. ISBN 978-8178331829.

- ↑ Jung, Woo-Hyuk; Ha, Eun-Ju; Chung, Il doo; Lee, Jang-Oo (2008-08-01). "Synthesis of aniline-based azopolymers for surface relief grating". Macromolecular Research. 16 (6): 532–538. doi:10.1007/BF03218555. ISSN 2092-7673. S2CID 94372490.

- ↑ Pastarnokienė, Liepa; Jonikaitė-Švėgždienė, Jūratė; Lapinskaitė, Neringa; Kulbokaitė, Rūta; Bočkuvienė, Alma; Kochanė, Tatjana; Makuška, Ričardas (2023-07-01). "The effect of reactive diluents on curing of epoxy resins and properties of the cured epoxy coatings". Journal of Coatings Technology and Research. 20 (4): 1207–1221. doi:10.1007/s11998-022-00737-4. ISSN 1935-3804. S2CID 256749849.

- ↑ Matějka, Libor; Dušek, Karel; Dobáš, Ivan (1985-10-01). "Curing of epoxy resins with amines". Polymer Bulletin. 14 (3): 309–315. doi:10.1007/BF00254954. ISSN 1436-2449. S2CID 92434408.

- ↑ Khalina, Morteza; Beheshty, Mohammad Hosain; Salimi, Ali (2019-08-01). "The effect of reactive diluent on mechanical properties and microstructure of epoxy resins". Polymer Bulletin. 76 (8): 3905–3927. doi:10.1007/s00289-018-2577-6. ISSN 1436-2449. S2CID 105389177.

- ↑ Roşu, D; Caşcaval, C. N; Mustątǎ, F; Ciobanu, C (2002-02-07). "Cure kinetics of epoxy resins studied by non-isothermal DSC data". Thermochimica Acta. 383 (1): 119–127. doi:10.1016/S0040-6031(01)00672-4. ISSN 0040-6031.

- ↑ Klee, Joachim; Flammersheim, Hans Jurgen (2002). "Linear Addition Polymers and Cyclic Oligomers of N,N-Diglycidyl Aniline and Amines -Uncrosslinked Epoxide Amine Addition Polymers". Macromolecular Chemistry and Physics (203 ed.). 203: 100–108. doi:10.1002/1521-3935(20020101)203:1<100::AID-MACP100>3.0.CO;2-J.

- ↑ John, N. A. St; George, G. A. (1994-01-01). "Diglycidyl amine — epoxy resin networks: Kinetics and mechanisms of cure". Progress in Polymer Science. 19 (5): 755–795. doi:10.1016/0079-6700(94)90032-9. ISSN 0079-6700.

- ↑ Ergozhin, E. E.; Begenova, B. E.; Chalov, T. K. (2007-03-01). "Synthesis and study of physicochemical, acid-base, and complexing properties of ion exchangers based on glycidyl derivatives of aromatic compounds and polyamines". Russian Journal of Applied Chemistry. 80 (3): 472–476. doi:10.1134/S1070427207030238. ISSN 1608-3296. S2CID 92895375.

- ↑ Johncock, P.; Cunliffe, A. V. (1992-01-01). "Structural features in epoxy networks from N,N-diglycidyl epoxies and amines: 2. Ether ring formation and polymer structure in the reactions of N,N-diglycidylaniline with aniline and substituted anilines". Polymer. 33 (11): 2392–2401. doi:10.1016/0032-3861(92)90533-3. ISSN 0032-3861.

- ↑ John, N. A. St; George, G. A. (1994-01-01). "Diglycidyl amine — epoxy resin networks: Kinetics and mechanisms of cure". Progress in Polymer Science. 19 (5): 755–795. doi:10.1016/0079-6700(94)90032-9. ISSN 0079-6700.

- ↑ Seiler, J.P. (March 1984). "The mutagenicity of mono- and di-functional aromatic glycidyl compounds". Mutation Research/Genetic Toxicology. 135 (3): 159–167. doi:10.1016/0165-1218(84)90116-2. PMID 6369127.

Further reading

- Epoxy resin technology. Paul F. Bruins, Polytechnic Institute of Brooklyn. New York: Interscience Publishers. 1968. ISBN 0-470-11390-1. OCLC 182890.

{{cite book}}: CS1 maint: others (link) - Flick, Ernest W. (1993). Epoxy resins, curing agents, compounds, and modifiers : an industrial guide. Park Ridge, NJ. ISBN 978-0-8155-1708-5. OCLC 915134542.

{{cite book}}: CS1 maint: location missing publisher (link)