Inverted Brayton Cycle (IBC) (also known as Subatmospheric Brayton cycle) is another version of the conventional Brayton cycle but with a turbine positioned immediately in the inlet of the system.[1][2][3]

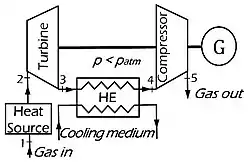

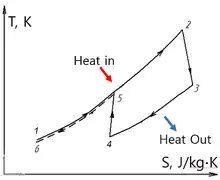

(1–2) – heat addition; (2–3) – turbine expansion; (3–4) – cooling; (4–5) – compression; (5–6) – release to atmosphere

(1–2) – heat addition; (2–3) – turbine expansion; (3–4) – cooling; (4–5) – compression; (5–6) – release to atmosphere

Functionality

Incoming air may be heated up in the combustion chamber, in the heat exchanger, or the system may directly receive hot exhaust gas from an engine or some technological process. Been heated up in one of these ways, the gas expands in the turbine from pressure around the atmospheric to the subatmospheric one, after the turbine, created by the compressor located further in the gas duct. The gas should be cooled down in the heat-exchanger between the turbine and compressor to provide the difference in the work received in the turbine and the work needed for the compressor to maintain the subatmospheric pressure after the turbine. After the compressor, the gas is released to the atmosphere with the pressure close to the atmospheric one. Alternatively, the gas can be cooled down after the compressor again, as it gains some heat in the compression process, and then released. The heat received in the heat-exchangers between the turbine and compressor and after the compressor may be used for heating, providing the cogeneration mode of the system operation. The basic scheme of the IBC and temperature-enthalpy diagram are presented in figures 1 and 2.[4] For external heat sources or high temperature storage systems, the closed process design of the inverted Brayton Cycle is also possible. The overall efficiency can thus be significantly increased.[5]

References

- ↑ Bianchi, M.; Montenegro, Galo; Peretto, A. (2002-07-01). "Inverted Brayton Cycle Employment for Low-Temperature Cogenerative Applications". Journal of Engineering for Gas Turbines and Power. 124 (3): 561–565. doi:10.1115/1.1447237. Retrieved 2019-11-14.

- ↑ Kennedy, Ian; Chen, Zhihang; Ceen, Bob; Jones, Simon; Copeland, Colin D. (2019-03-01). "Experimental Investigation of an Inverted Brayton Cycle for Exhaust Gas Energy Recovery". Journal of Engineering for Gas Turbines and Power. U.S.: American Society of Mechanical Engineers. 141 (3). doi:10.1115/1.4041109.

- ↑ Weber, Justin; Straub, Douglas (2010). "Inverted Brayton Cycle for use with Chemical Looping Combustion". 8th Annual International Energy Conversion Engineering Conference. American Institute of Aeronautics and Astronautics. doi:10.2514/6.2010-6606. ISBN 978-1-62410-156-4. S2CID 131554459.

- ↑ Abrosimov, Kirill A.; Baccioli, Andrea; Bischi, Aldo (2020-03-01). "Techno-economic analysis of combined inverted Brayton – Organic Rankine cycle for high-temperature waste heat recovery". Energy Conversion and Management. Elsevier Ltd. 207: 112336. doi:10.1016/j.enconman.2019.112336. S2CID 242827611.

- ↑ Holy, Felix; Textor, Michel; Lechner, Stefan (2021-12-01). "Gas turbine cogeneration concepts for the pressureless discharge of high temperature thermal energy storage units". Journal of Energy Storage. 44: 103283. doi:10.1016/j.est.2021.103283. ISSN 2352-152X.