Isogrid is a type of partially hollowed-out structure formed usually from a single metal plate (or face sheet) with triangular integral stiffening ribs (often called stringers). It was patented by McDonnell Douglas (now part of Boeing).[1] It is extremely light and stiff.[2] Compared to other materials, it is expensive to manufacture, and so it is restricted to spaceflight applications and some particularly critical parts of more general aerospace use.

Theory and design

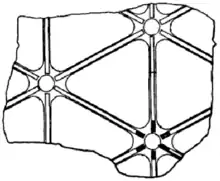

Isogrid structures are related to sandwich-structured composite panels; both can be modeled using sandwich theory, which describes structures with separated, stiff face sheets and a lighter interconnecting layer. Isogrids are manufactured from single sheets of material and with large-scale triangular openings, and an open pattern to the flanges, compared to closed sheets and foam or honeycomb structures for the sandwich-composite structures.

Isogrid structures are constituted by a thin skin reinforced with a lattice structure. Such structures are adopted in the aeronautical industry since they present both structural resistance and lightness.[4]

The triangular pattern is very efficient because it retains rigidity while saving material and therefore weight. The term isogrid is used because the structure acts like an isotropic material, with equal properties measured in any direction, and grid, referring to the sheet and stiffeners structure.

A similar variant is the orthogrid (sometimes called a waffle grid), which uses rectangular rather than triangular openings. This is not isotropic (has different properties from different angles), but matches many use cases well and is easier to manufacture.

Traditionally, the equilateral triangle pattern was used because it was amenable to simplified analysis.[5] [6] Since the equilateral triangle pattern has isotropic strength characteristics (no preferential direction), it was named isogrid.[5]

Manufacturing

The stiffeners of an isogrid are generally machined from one face of a single sheet of material such as aluminum with a CNC milling machine. A thickness less than 0.040 in. (1.0 millimeter) might require chemical milling processes.[7]

A major push has been made toward additive manufacturing techniques due to a decrease in overall material and production costs and high efficiency and accuracy while providing control over parameters like porosity. Also, the ease of prototype manufacturing for testing purposes has made a huge contribution.[8]

Composite isogrids are rib-skin configurations, where at least a part of the rib is a different material from the skin, the composite assembled by various manual or automated processes.[9] This can give extremely high strength-weight ratios.[10]

Uses

Isogrid panels form self-stiffened structures where low weight, stiffness, strength and damage tolerance are important, such as in aircraft or space vehicles. Aerospace isogrid structures include payload shrouds and boosters, which must support the full weight of upper stages and payloads under high G loads. Their open configuration with a single, sealed sheet facing the outside makes them especially useful for propellant tanks for rockets, where sealing the propellant in, but allowing it to drain in use or maintenance are necessary features.

Examples

Some spacecraft and launch vehicles which use isogrid structures include:

- Delta families[5][11]

- Atlas families[12]

- Skylab spacestation Orbital Workshop module[5]

- SLS Core Stage[13]

- CST-100 Starliner[14]

- Spacex Crew Dragon[15]

- Orthogrids (Waffle grids with a square pattern) were used in the Saturn rocket tanks, due to the lower cost and ease of manufacture[16]

- Orthogrids are also planned for the Vulcan rocket.[17]

See also

References

- ↑ Huybrechts, Steven M.; Hahn, Steven E.; Meink, Troy E. (July 5–9, 1999). GRID STIFFENED STRUCTURES: A SURVEY OF FABRICATION, ANALYSIS AND DESIGN METHODS (PDF). Proceedings of the 1999 International Conference on Composite Materials. Paris, France. Retrieved Jan 10, 2020.

The McDonnell-Douglas Corporation (now part of The Boeing Company) holds the patent rights for development of the first aluminum isogrid

- ↑ Black, Jonathan T. (2006). NEW ULTRA-LIGHTWEIGHT STIFF PANELS FOR SPACE APERTURES (PhD). University of Kentucky Doctoral Dissertations. Retrieved Jan 10, 2020.

- ↑ US patent 4012549, Paul Slysh, "High strength composite structure", published Oct 10, 1974, issued Mar 15, 1977

- ↑ Sorrentino, L.; Marchetti, M.; Bellini, C.; Delfini, A.; Albano, M. (2016-05-20). "Design and manufacturing of an isogrid structure in composite material: Numerical and experimental results". Composite Structures. 143: 189–201. doi:10.1016/j.compstruct.2016.02.043. ISSN 0263-8223.

- 1 2 3 4 McDonnell Douglas Astronautics Company (February 1973). Isogrid Design Handbook (PDF) (Technical report). NASA. p. 1.0.002 (12/252). NASA CR-124075. Retrieved Jan 10, 2020.

- ↑ Meyer, R. R; Harwood, O. P. (Oct 1, 1973) [1973]. Isogrid design handbook. Marshall Space Flight Center. 19730000395.

- ↑ Slysh, Paul. "The Isogrid". Archived from the original on March 24, 2012. Retrieved May 27, 2011.

- ↑ Tripathi, Kukreja, Madan. "Evolution in Manufacturing of Grid Stiffened Structures through CAM and Additive Techniques". Research Gate.

{{cite web}}: CS1 maint: multiple names: authors list (link) - ↑ Huybrechts, Steven; Troy E. Meink; Peter M. Wegner; Jeff M. Ganley (2002). "Manufacturing theory for advanced grid stiffened structures". Composites Part A: Applied Science and Manufacturing. Elsevier. 33 (2): 155–161. doi:10.1016/S1359-835X(01)00113-0. Archived from the original on March 4, 2016. Retrieved 26 May 2012.

- ↑ Wegner, Peter M.; Higgins, John E.; VanWest, Barry P. (2002). "Application of Advanced Grid-Stiffened Structures Technology to the Minotaur Payload Fairing". 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Denver, CO. Archived from the original on May 27, 2012.

- ↑ Knighton, D. J. (Sep 1, 1972) [1972], "Delta launch vehicle isogrid structure NASTRAN analysis", Nastran: Users' Experiences, Goddard Space Flight Center, hdl:2060/19720025227, archived from the original on January 29, 2021, retrieved July 7, 2017

{{citation}}: CS1 maint: bot: original URL status unknown (link) - ↑ "Atlas V 500 series" (PDF). United Launch Alliance. Archived from the original (PDF) on 2016-04-09. Retrieved 2016-06-06.

- ↑ Kyle, Ed (Jan 26, 2014). "Progress on NASA's Space Launch System and Orion". Space Launch Report. Retrieved Jan 10, 2020.

Boeing's SLS core will use AL-2219 Aluminum machined with isogrids

- ↑ Young, Anthony (23 June 2014). "Boeing displays CST-100 progress at Kennedy Space Center". The Space Review. SpaceNews. Retrieved 25 October 2017.

- ↑ Editor, SpaceRef (2010-10-05). "SpaceX Update: COTS Demonstration Flight 1 (with photos)". SpaceRef. Retrieved 2022-11-03.

{{cite web}}:|last=has generic name (help) - ↑ Wagner, W. A. (May 1, 1974) [1974], Liquid rocket metal tanks and tank components, NASA Lewis Research Center, pp. 55–58, hdl:2060/19750004950, archived from the original on January 30, 2021, retrieved November 26, 2019

{{citation}}: CS1 maint: bot: original URL status unknown (link) - ↑ Bruno, Tory [@torybruno] (April 20, 2017). "Orthogrid trial panel for Vulcan Rocket propellant tank. (Bigger than it looks...)" (Tweet). Retrieved Jan 10, 2020 – via Twitter.

External links

- Isogrid Plate Modeling, Dr Wiliam Case, 1997

- Isogrid Design Handbook, NASA CR-124075, McDonnell Douglas, 1973

- Advanced Grid Stiffened Composite Structures Archived 2006-04-22 at the Wayback Machine

- Isogrid - Shell Structures Tools, 1990 Archived 2011-07-13 at the Wayback Machine

- Quarter Isogrid used in Surfboard Construction