| |

| |

| Names | |

|---|---|

| Other names

Tungstosilicic acid | |

| Identifiers | |

| |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.206.333 |

PubChem CID |

|

| UNII |

|

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| H4[SiW12O40] | |

| Molar mass | 2878.2 g/mol |

| Appearance | White solid |

| Melting point | 53 °C (127 °F; 326 K) |

| Structure | |

| zero | |

| Hazards | |

| GHS labelling: | |

| |

| Danger | |

| H314, H315, H319, H335, H412 | |

| P260, P261, P264, P271, P273, P280, P301+P330+P331, P302+P352, P303+P361+P353, P304+P340, P305+P351+P338, P310, P312, P321, P332+P313, P337+P313, P362, P363, P403+P233, P405, P501 | |

| Flash point | Non-flammable |

| Related compounds | |

Related heteropoly acids |

Phosphotungstic acid |

Related compounds |

Tungsten trioxide Tungstic acid |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

Silicotungstic acid or tungstosilicic acid is a heteropoly acid with the chemical formula H4[SiW12O40]. It forms hydrates H4[SiW12O40]·nH2O. In freshly prepared samples, n is approximately 29, but after prolonged desiccation, n = 6.[1] It is a white solid although impure samples appear yellow. It is used as a catalyst in the chemical industry.[2]

Applications

Silicotungstic acid is used to manufacture ethyl acetate by the alkylation of acetic acid by ethylene:

- C2H4 + CH3CO2H → CH3CO2C2H5

It has also been commercialized for the oxidation of ethylene to acetic acid:[2]

- C2H4 + O2 → CH3CO2H

This route is claimed as a "greener" than methanol carbonylation. The heteropoly acid is dispersed on silica gel at 20-30 wt% to maximize catalytic ability.

It has also recently been proposed as a mediator in production of hydrogen through electrolysis of water by a process that would reduce the danger of explosion while allowing efficient hydrogen production at low current densities, conducive to hydrogen production using renewable energy.[3]

Synthesis and structure

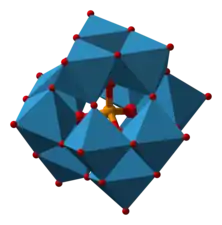

The free acid is produced by combining sodium silicate and tungsten trioxide followed treatment of the mixture with hydrochloric acid.[1][4] The polyoxo cluster adopts a Keggin structure, with Td point group symmetry.

Hazards

Silicotungstic acid is an irritating and odorless substance.

References

- 1 2 Dias, J. A.; Dias, S. C. L.; Caliman, E. (2014). "Keggin Structure Polyoxometalates". Keggin Structure Polyoxoometalates. Inorganic Syntheses. Vol. 36. p. 210-217. doi:10.1002/9781118744994.ch39. ISBN 9781118744994.

- 1 2 Misono, Makoto (2009). "Recent progress in the practical applications of heteropolyacid and perovskite catalysts: Catalytic technology for the sustainable society". Catalysis Today. 144 (3–4): 285–291. doi:10.1016/j.cattod.2008.10.054.

- ↑ Rausch, Benjamin; Symes, Mark D.; Chisholm, Greig; Cronin, Leroy (September 12, 2014). "Decoupled catalytic hydrogen evolution from a molecular metal oxide redox mediator in water splitting". Science. American Association for the Advancement of Science. 345 (6202): 1326–1330. Bibcode:2014Sci...345.1326R. doi:10.1126/science.1257443. PMID 25214625. S2CID 20572410.

- ↑ Handbook of Preparative Inorganic Chemistry, 2nd Ed. Edited by G. Brauer, Academic Press, 1963, NY.